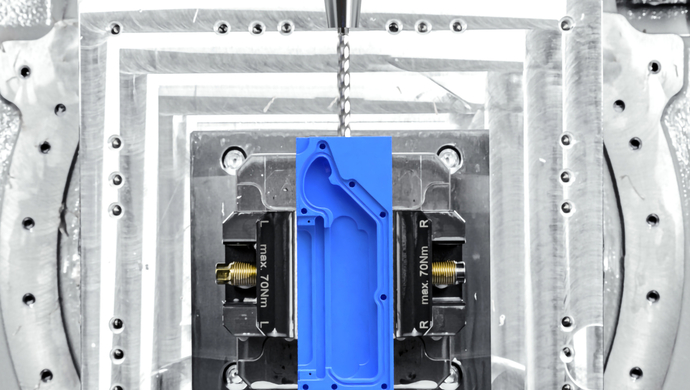

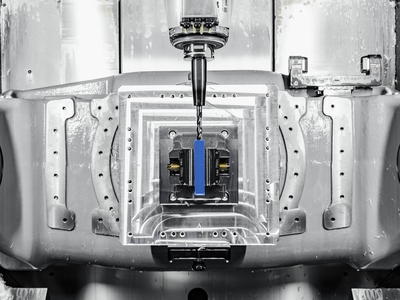

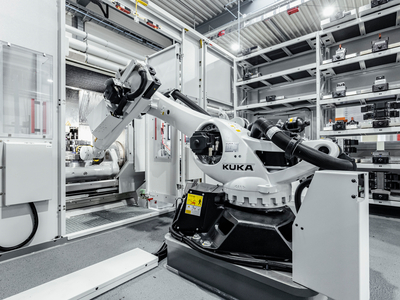

Dimensional stability in the machining process

At the faigle Group, thermoplastics are at the heart of everything we do. faigle Industrieplast GmbH has been specialising in the production of machined finished parts for 50 years. The company has extensive expertise when it comes to the dimensional stability of the various types of plastic in the machining process, as well as the specific intermediate processing steps required to achieve the best results.

Our machines are configured precisely for plastics processing, which translates into exceptionally efficient processes. This is why long-standing metal-machining businesses also take advantage of faigle’s services, allowing them to add top-quality plastics to their portfolios.

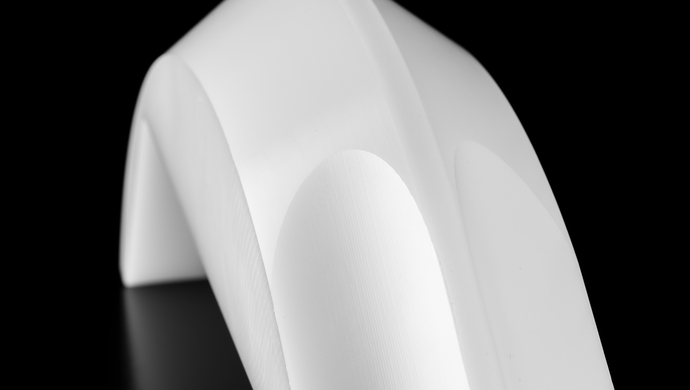

Precise layout of finished parts

Whether it’s complex one-off production or high-precision volume manufacturing, optimised layout of finished parts ensures ideal manufacturing processes – from both a technical and financial perspective.

Application-engineering consultation with our experts during the planning and design phase gives you the support you need when choosing materials: depending on the customer’s requirements, finding the most suitable material is a key success and cost factor. We’ll be happy to talk to you.

Design set-up

We can make proposals for potential geometries and tolerances, and provide information on the various processing parameters. We’re happy to put our experience at your disposal during the design phase.

The faigle consulting teamMaterials

faigle has 600,000kg of semifinished products in stock, in over 1,200 dimensions and made from more than 100 different materials. Speed, flexibility and outstanding customer service are our top priorities.

Materials

01.

02.

03.

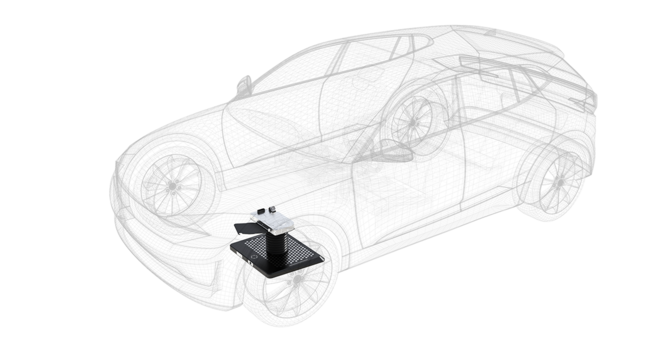

As we all know, electric vehicles can only cover a limited distance before they need recharging. So a widespread network of charging points will need to be put in place in cities to keep millions of e-vehicles on the road. Charging infrastructure has to be robust and weather-resistant so that it can be installed and operated in various settings, such as public spaces or outdoor areas. But at the same time, charging systems must not create barriers or trip hazards. Produced by high-tech company Easelink, the automated conductive Matrix Charging® technology provides a solution for the urban vehicle charging infrastructure of the future.

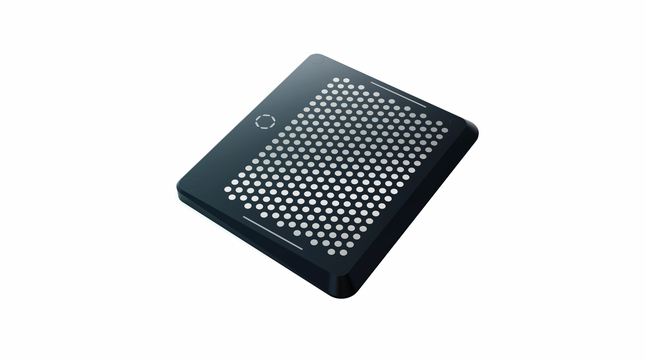

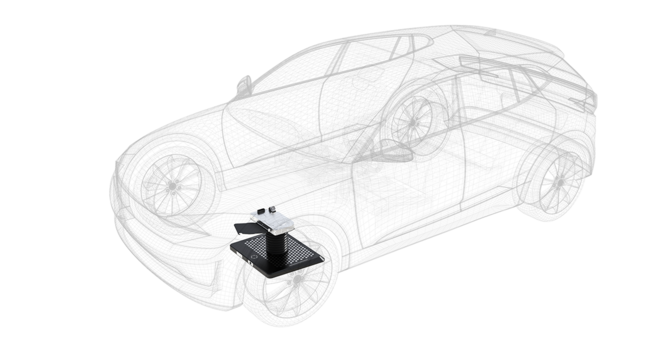

The system consists of two components: the Matrix Charging® Connector fitted on the vehicle underbody, and the Matrix Charging® Pad, which is installed directly in the parking space. As soon as the vehicle parks above the Pad, the Connector extends downwards from the underbody, connects with the Pad below, and the vehicle is charged automatically via the conductive connection. The technology is highly robust, as the Pad can be embedded in the parking space to create a flat surface. This means an extensive network of charging points can be installed in urban settings.

Alongside the system’s robustness, the automated charging process translates into far greater convenience for e-vehicle users. With Matrix Charging®, attaching and unplugging cables is a thing of the past.

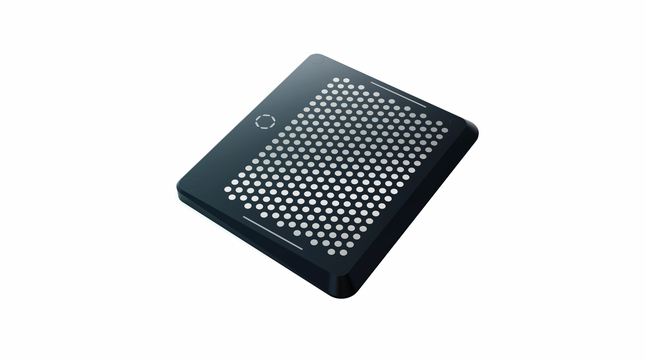

Easelink teamed up with faigle for the current Matrix Charging® prototype generation, with the aim of producing a particularly hard-wearing enclosure made from rigid PVC for the Matrix Charging® Pad.

The Pad is resistant against chemical, mechanical, temperature-related and electromagnetic influences, and can withstand wheel loads of up to 2,500kg. The integrated cleaning function in the Matrix Charging® Connector clears various surface contaminants from the Matrix Charging® Pad, which ensures a reliable connection for recharging.

With the Matrix Charging® system, the charging infrastructure is concealed beneath the vehicle. All that is required at the parking facility is a flat surface, so that the Matrix Charging® Pad can be embedded flush in the parking spaces; alternatively, the Pad can be placed on the surface of the parking space. This means that no space is lost and no additional obstacles are created. In many parking facilities (for vehicle fleets, at supermarkets and in public car parks, for example), the Pad must be designed to withstand the loads generated by commercial vehicles. Weather-related factors and the influence of dirt and road salt also need to be considered when it comes to installation. Integrating the charging system into the surface of the parking space is the most practical solution.

The mechanical solution used for the robust, cost-effective and easy-to-use charging equipment on the vehicle is a simple, unidirectional upward and downward movement.

The cost-effective, highly efficient design of Matrix Charging® was developed to allow for installation in private garages as well as in public spaces.

Read more about the technology:

Use-Case Matrix Charging

As we all know, electric vehicles can only cover a limited distance before they need recharging. So a widespread network of charging points will need to be put in place in cities to keep millions of e-vehicles on the road. Charging infrastructure has to be robust and weather-resistant so that it can be installed and operated in various settings, such as public spaces or outdoor areas. But at the same time, charging systems must not create barriers or trip hazards. Produced by high-tech company Easelink, the automated conductive Matrix Charging® technology provides a solution for the urban vehicle charging infrastructure of the future.

The system consists of two components: the Matrix Charging® Connector fitted on the vehicle underbody, and the Matrix Charging® Pad, which is installed directly in the parking space. As soon as the vehicle parks above the Pad, the Connector extends downwards from the underbody, connects with the Pad below, and the vehicle is charged automatically via the conductive connection. The technology is highly robust, as the Pad can be embedded in the parking space to create a flat surface. This means an extensive network of charging points can be installed in urban settings.

Alongside the system’s robustness, the automated charging process translates into far greater convenience for e-vehicle users. With Matrix Charging®, attaching and unplugging cables is a thing of the past.

02.

Implementation

Easelink teamed up with faigle for the current Matrix Charging® prototype generation, with the aim of producing a particularly hard-wearing enclosure made from rigid PVC for the Matrix Charging® Pad.

The Pad is resistant against chemical, mechanical, temperature-related and electromagnetic influences, and can withstand wheel loads of up to 2,500kg. The integrated cleaning function in the Matrix Charging® Connector clears various surface contaminants from the Matrix Charging® Pad, which ensures a reliable connection for recharging.

03.

How it works

With the Matrix Charging® system, the charging infrastructure is concealed beneath the vehicle. All that is required at the parking facility is a flat surface, so that the Matrix Charging® Pad can be embedded flush in the parking spaces; alternatively, the Pad can be placed on the surface of the parking space. This means that no space is lost and no additional obstacles are created. In many parking facilities (for vehicle fleets, at supermarkets and in public car parks, for example), the Pad must be designed to withstand the loads generated by commercial vehicles. Weather-related factors and the influence of dirt and road salt also need to be considered when it comes to installation. Integrating the charging system into the surface of the parking space is the most practical solution.

The mechanical solution used for the robust, cost-effective and easy-to-use charging equipment on the vehicle is a simple, unidirectional upward and downward movement.

The cost-effective, highly efficient design of Matrix Charging® was developed to allow for installation in private garages as well as in public spaces.

Read more about the technology:

Marco Blum

CEO OF FAIGLE INDUSTRIEPLAST GMBH

How can I help you?

Hi, I’m Helmut Schneller. I’d be happy to talk to you about our products and answer any questions you might have on our custom solutions.