01.

02.

03.

04.

Used in escalators and moving walks, step and chain rollers are highly stressed components. Chain rollers have a key function, absorbing all loads resulting from the weight of the chain and chain hoist, as well as those occurring in the drive wheel. The weight of the steps and the users is largely borne by the step rollers. Flawless functionality, robustness and longevity are critical for both types of roller.

HD rollers are mainly used in high-traffic escalators, for example in underground stations, where the combination of escalator height and continuous operation place huge demands on the rollers’ durability.

3C rollers are predominantly used in applications where the technical specifications call for a metal hub.

faigle plastic rollers provide:

- Excellent comfort for users and smooth operation

- No hydrolysis-related ageing or damage – reliable operation in damp environments

- Compliance with all application requirements, coupled with efficient use of material

- Original OEM-approved part – risk-free application, including in replacement part market

- The state of the art for the escalator industry – approved by OEMs, operators and public authorities

The tyre is made of PAS-PU H, a thermoplastic polyurethane. This material has all of the necessary properties, including resistance to hydrolysis and microbes, as well as high abrasion resistance.

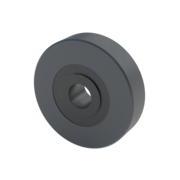

This tried-and-tested 1C roller, which features either a ball bearing or a plain bearing, has been on the market for decades and is in use in millions of walks and escalators. It has a ball or plain bearing and the bandage is snapped under pre-tension.

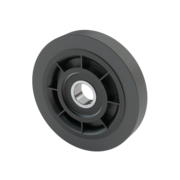

This 2C roller has a ball or plain bearing. The hub is made of glass-fibre-reinforced polyamide and the tyre from PAS-PU H. In order to withstand the significant loads generated by high-traffic escalators, the 2C roller is fitted with a thicker tyre and reinforced hub.

The running surface of the 1C, 2C and 2C HD rollers is ground, which ensures excellent dimensional stability and good concentricity.

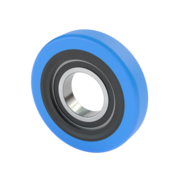

This 3C roller was specifically developed for high-traffic escalators. In line with operators’ specifications for these kinds of escalator, it comprises a metal hub made from steel or aluminium surrounded by glass fibre reinforced polyamide, a ball bearing and a tyre made of PAS-PU H, a hydrolysis-resistant thermoplastic polyurethane. The tyre is harder than on the 1C and 2C rollers. The injection-moulded design ensures reliable tyre bonding coupled with high process integrity.

- Ideal for continuous operation, especially in high-traffic escalators (2C HD Roller)

- High load-bearing capacity ideal for greater escalator heights (2C HD Roller)

- Satisfies customer demand for metal hubs (3C Roller)

- Ideal for greater heights and continuous operation, especially in high-traffic escalators (3C Roller)

Of all the components in an escalator, the roller ball bearing is the most sensitive to environmental and system changes. If dust, dirt, detergents, solvents or general moisture get into the bearing, this can result in a breakdown. The same goes for corrosion or loss of grease in the ball bearing.

Based on the principle of a labyrinth seal, our ball bearing protection system is also filled with ball bearing grease. This reduces exposure to environmental influences and protects against premature corrosion. All faigle rollers are fitted with a groove into which the ball bearing protection system can be snapped.

- Protects bearings against environmental effects – ideal for trouble-free operation in outdoor applications

- Protects the bearing against premature corrosion

- Contactless sealing effect guards against additional running resistance

- Can be snapped into all faigle rollers: can be used wherever required – the choice is yours

- Suitable for most escalator types – easy retrofitting

Product information

Used in escalators and moving walks, step and chain rollers are highly stressed components. Chain rollers have a key function, absorbing all loads resulting from the weight of the chain and chain hoist, as well as those occurring in the drive wheel. The weight of the steps and the users is largely borne by the step rollers. Flawless functionality, robustness and longevity are critical for both types of roller.

HD rollers are mainly used in high-traffic escalators, for example in underground stations, where the combination of escalator height and continuous operation place huge demands on the rollers’ durability.

3C rollers are predominantly used in applications where the technical specifications call for a metal hub.

faigle plastic rollers provide:

- Excellent comfort for users and smooth operation

- No hydrolysis-related ageing or damage – reliable operation in damp environments

- Compliance with all application requirements, coupled with efficient use of material

- Original OEM-approved part – risk-free application, including in replacement part market

- The state of the art for the escalator industry – approved by OEMs, operators and public authorities

The tyre is made of PAS-PU H, a thermoplastic polyurethane. This material has all of the necessary properties, including resistance to hydrolysis and microbes, as well as high abrasion resistance.

This tried-and-tested 1C roller, which features either a ball bearing or a plain bearing, has been on the market for decades and is in use in millions of walks and escalators. It has a ball or plain bearing and the bandage is snapped under pre-tension.

This 2C roller has a ball or plain bearing. The hub is made of glass-fibre-reinforced polyamide and the tyre from PAS-PU H. In order to withstand the significant loads generated by high-traffic escalators, the 2C roller is fitted with a thicker tyre and reinforced hub.

The running surface of the 1C, 2C and 2C HD rollers is ground, which ensures excellent dimensional stability and good concentricity.

This 3C roller was specifically developed for high-traffic escalators. In line with operators’ specifications for these kinds of escalator, it comprises a metal hub made from steel or aluminium surrounded by glass fibre reinforced polyamide, a ball bearing and a tyre made of PAS-PU H, a hydrolysis-resistant thermoplastic polyurethane. The tyre is harder than on the 1C and 2C rollers. The injection-moulded design ensures reliable tyre bonding coupled with high process integrity.

- Ideal for continuous operation, especially in high-traffic escalators (2C HD Roller)

- High load-bearing capacity ideal for greater escalator heights (2C HD Roller)

- Satisfies customer demand for metal hubs (3C Roller)

- Ideal for greater heights and continuous operation, especially in high-traffic escalators (3C Roller)

Of all the components in an escalator, the roller ball bearing is the most sensitive to environmental and system changes. If dust, dirt, detergents, solvents or general moisture get into the bearing, this can result in a breakdown. The same goes for corrosion or loss of grease in the ball bearing.

Based on the principle of a labyrinth seal, our ball bearing protection system is also filled with ball bearing grease. This reduces exposure to environmental influences and protects against premature corrosion. All faigle rollers are fitted with a groove into which the ball bearing protection system can be snapped.

- Protects bearings against environmental effects – ideal for trouble-free operation in outdoor applications

- Protects the bearing against premature corrosion

- Contactless sealing effect guards against additional running resistance

- Can be snapped into all faigle rollers: can be used wherever required – the choice is yours

- Suitable for most escalator types – easy retrofitting