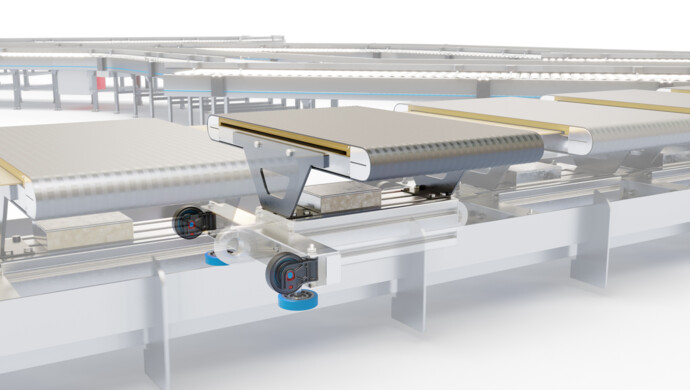

Hard (AT), Stuttgart (DE). faigle Kunststoffe’s decades of experience show that lightweight parts help to save energy at intralogistics facilities – making them more environmentally friendly in the long run. The Vorarlberg-based company is constantly looking for ways to optimise the construction of its energy-efficient components. The plastics specialist’s newly developed wheel holders, which are used in parcel sortation and baggage handling system parts, feature long-lasting, lightweight injection-moulded plastic components. At LogiMAT 2023 in Stuttgart, the faigle Group will also be presenting yet another innovation: running wheels made from climate-friendly plastics for the intralogistics sector.

Components for parcel sortation and baggage handling systems need to withstand significant loads, as well as retaining their dimensional stability during continuous operation. In parallel, companies are always on the lookout for new ways to make their facilities more energy-efficient. And with a view to meeting these requirements, faigle Kunststoffe – a member of the faigle Group – has developed a new wheel assembly: the faigle wheel holder. The patented assembly comprises a wheel, wheel fork, pivot bearings, shaft, shaft damper and clips – with plastic used as far as possible to make all parts.