faigle Group - the plastics experts

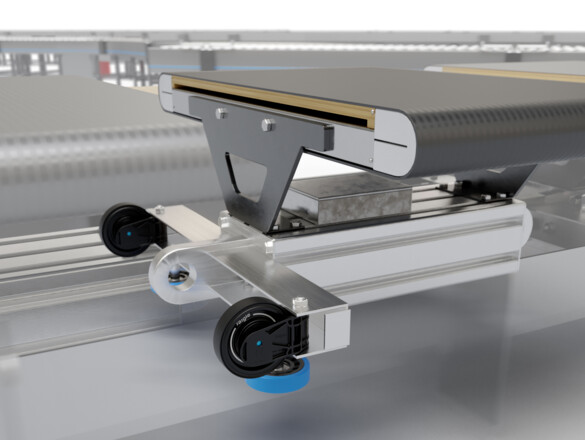

Swivel wheel comfort – faigle’s new wheel assembly

an innovative design concept for sortation systems

Cut drive energy requirements in day-to-day operations by up to 25% and feel the benefits of quick and easy, tool-free assembly. Deployed in various types of sortation equipment, the system is ideal for all applications thanks to its high scalability. Our strict quality standards deliver outstanding reliability and durability.

A family company

Developing and producing groundbreaking technologies, materials and new products are faigle’s vision, the recipe for its success and a challenge all rolled into one – day in, day out. Consulting, prototype construction, test samples, quality testing and modifications right through to the end result – perfectly aligned to specifications and the customer’s requirements. This is the DNA of faigle, a group with plants in four locations, highly specialised disciplines, a wealth of expertise, and international, blended teams. Moving forward with a pioneering spirit and shaping the future with confidence are the foundations for the success of the Faigle family and the family business, now in its third generation.

faigle - plastics technology

Tribology is the study of friction. It is our speciality and in many cases the key to success for our customers. Friction between plastic parts is vital when it comes to the efficiency of escalators, intralogistics systems, centre pivot liners and industrial plants. Success often depends on whether a plastic part sticks or slides, so finding the right balance in terms of friction is essential for reliable operations. Service life and lubricants are also important cost factors. We can identify in advance the material that is best suited to a particular application. Various measuring procedures, coupled with the extensive experience we have gained in the course of endurance testing enable our experts to choose the right materials, as well as calculating the ideal dimensions for components and selecting the optimum interacting surfaces for reliable operations.